You know how important the detailing stage is to any kind of construction – and for cold formed steel (CFS) construction, it’s even more vital. Whether you’re working on a small home or an enormous commercial complex, accuracy and adaptability are the keys to ensuring your project is a success.

You know how important the detailing stage is to any kind of construction – and for cold formed steel (CFS) construction, it’s even more vital. Whether you’re working on a small home or an enormous commercial complex, accuracy and adaptability are the keys to ensuring your project is a success.

So how do you ensure that you’re using the right software? Look at the experts behind it.Meet the team: Introducing Craig Allen

Craig Allen, a design consultant working on FRAMECAD Structure & Detailer, has spent nearly 9 years with FRAMECAD. Through that time, he’s worked with customers and support staff across the globe – training and supporting customers to get the most out of their FRAMECAD design software, and taking their feedback into software development. Prior to joining the team, Craig was a timber detailer for 18 years – and he says the decision to move to FRAMECAD and work with cold formed steel was a great one.

“I chose to work for FRAMECAD because of their drive for innovation, the passion in the team for what they do, and also to be a part of the change in the construction industry that FRAMECAD is driving,” shares Craig.

“What makes the FRAMECAD System and constructing with cold formed steel so great is that it can greatly reduce the cost of the build and construction time, and it’s more accurate and requires less labour to construct.”

Reducing friction throughout detailing

Too often, detailing software is kept separate from the machines on which steel will be rolled. Design information will be entered into the software, then have to be transferred to machinery manually in order to start production. Besides being time consuming, this can cause issues with accuracy, as the inevitable human error that’s involved can kick in.

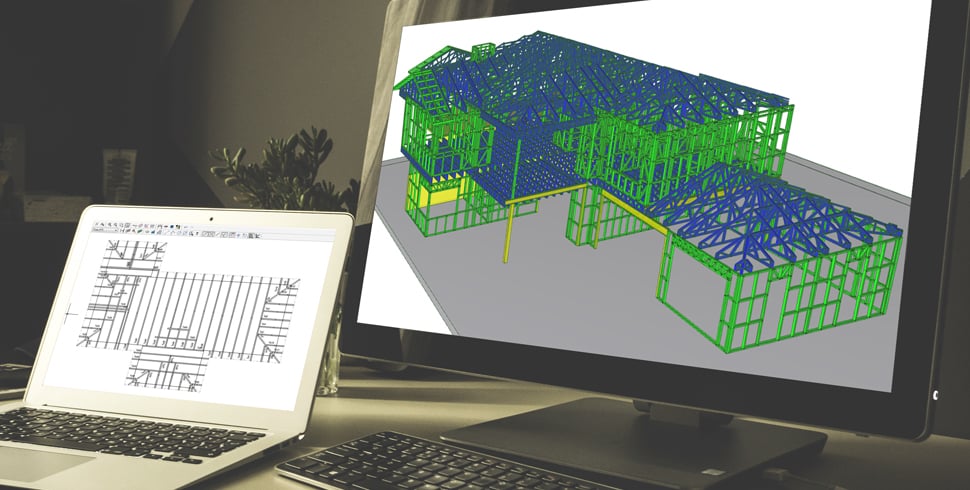

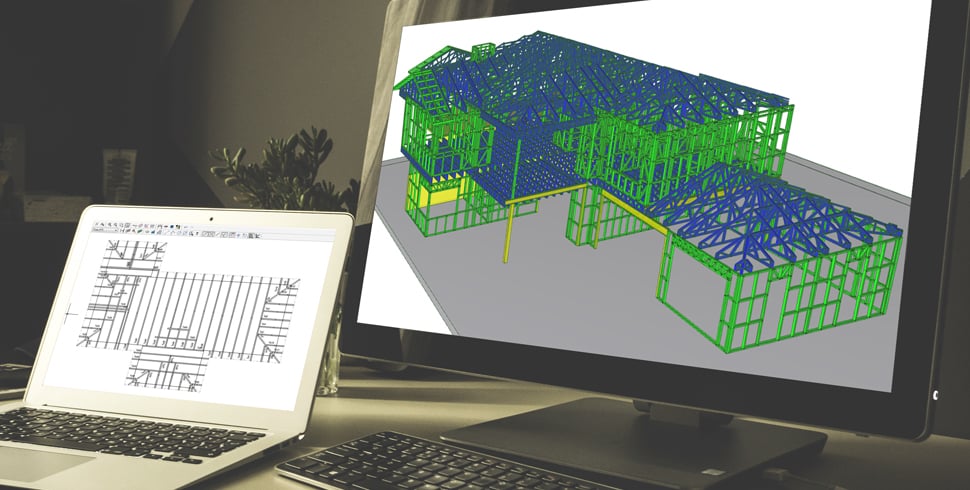

FRAMECAD Detailer is designed to talk directly to FRAMECAD Factory, the software which runs all our FRAMECAD machines, as well as to FRAMECAD Structure, our engineering software. Acting as the vital link between the two, it pulls through compliance and structural information from FRAMECAD Structure, allows you to double check the detailing and prepare for manufacturing, then passes all the information along to FRAMECAD Factory to enable complete accuracy and compliance during production on-site.

A steel framing detailer with more than two decades of experience, a key part of Craig’s role is testing and improving FRAMECAD Structure & Detailer to ensure it’s able to be used accurately in a vast array of design types. From small sheds right through to large apartment complexes, thousands of projects have been detailed using FRAMECAD software, leading to faster and more accurate production on-site.

“Using FRAMECAD software makes the engineering and detailing of a CFS building fast and accurate. Because of the 0.01mm accuracy of the FRAMECAD System, you can guarantee that the detailing is going to be correct and installed exactly as envisioned, which allows for great design flexibility.”

The speed with which construction can take place is a big factor in why the FRAMECAD System is used so extensively in developing nations which need fast and affordable housing.

Following a design-led process

Having worked in timber construction for 18 years, Craig is in a unique position to understand not only the benefits of CFS over traditional building methods, but also to understand the unique needs of detailers when it comes to transitioning into cold formed steel construction methods.

“CFS construction is a design-led process, meaning that the need for skills is higher at the design stage and less so on-site. Because the software is so accurate, it reduces the need for engineer involvement during the structural design stage, speeding up compliance, reducing engineering costs, and minimising room for error on-site,” describes Craig.

“Once CFS pieces are specified, they can quickly be produced at scale. Roll-forming machines can take steel coils and produce frames and other components that are precisely measured. Each piece will be consistent in quality and cut exactly as specified, and components can be produced in large quantities.”

That’s only possible because of a design-led process, engineering & detailing software which has been tried and tested in thousands of situations.

Support every step of the way

Having confidence in your detailing software is all about knowing who’s behind it.

Having proven itself in thousands of projects, FRAMECAD Structure & Detailer is particularly reliable because of FRAMECAD team members like Craig, who brings more than two decades of experience to designing, testing, and improving the software.

With Craig only a call or email away, you’ll always have someone you know available to walk you through difficult projects, provide exceptional training and inductions, or provide best practice advice. With Craig’s experience and expertise in the industry, it’s no wonder FRAMECAD is such a game-changer for cold formed steel detailing.