There have been some significant natural disasters across the globe. These disasters have devastated communities beyond what they could have imagined. These communities now have the monumental effort to rebuild using a construction method that will be more resilient to these disasters in the future.

The FRAMECAD solution is ideal for disaster zones as it is a robust construction method, has a high resilience to environmental challenges, it is fast to construct and has a straightforward design and build process. The integrated design-led build process takes into account the local environmental factors (cyclones, earthquakes etc). This helps to ensure safer communities in the future. FRAMECAD utilizes cold formed steel technology in its design and build process. This technology has been proven to be more resistant to natural disasters.

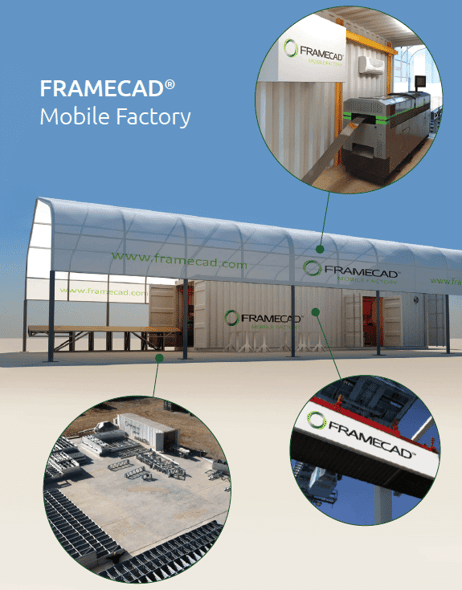

FRAMECAD has developed a Mobile Factory solution so that it is a complete, secure, self-contained manufacturing facility. It can be instantly located anywhere including remote areas and those areas affected by a natural disaster with little or no infrastructure. As a result, it is the ideal solution to rebuild after a hurricane or earthquake has impacted a community.

The FRAMECAD solution is flexible and can be part of the solution for high-volume projects and a wide range of construction needs. This paired with the Mobile Factory make the FRAMECAD solution the ideal method to construct.

Why Cold Formed Steel Construction is earthquake and cyclone Resistant

- Designed and engineered for earthquake and cyclone conditions - non-warping, non-twisting

- Being lightweight, it absorbs lateral movement

- Lightweight to erect in remote areas

- Compact and cheaper to transport

- Termite proof

- Galvanised steel material: rust/water/rain resistant

Build Back Better and Safer

- Safer to construct: less OH&S concerns than traditional wood frames

- Steel framing requires no additional preservative chemicals

- Minimal wastage, reducing the environmental impact from waste to landfill.

- All products from steel construction are reused, steel is also 100% recyclable.

FRAMECAD has a proven record and solid experience in operating in disaster areas:

- Turkish earthquake in 1999

- Sichuan Chinese earthquake in 2008

- Indonesian tsunami in 2010

- Haitian earthquake in 2010

- Pakistan earthquake in 2010

- Philippines typhoon in 2013

- Fijian cyclone in 2016

Watch now how FRAMECAD with the support of the Red Cross deployed the Mobile Factory solution to rebuild Vunikaikaloa Arya School in Fiji, after Cyclone Winston in only 10 days.

If you want a resilient construction method suitable to operate in disaster areas, talk to one of our experts today.

*This article was originally published in September 2017 and has since been updated.